Introduction

In today’s technology-driven world, efficient infrastructure planning is essential for businesses that rely on data centers, telecommunications systems, server rooms, and industrial IT environments. One of the most fundamental yet often misunderstood concepts in this field is rack units. Rack units play a critical role in determining how equipment is designed, installed, managed, and scaled within standardized racks.

As global sourcing and manufacturing expand—particularly with China-based suppliers serving international markets—the need for clarity around rack units has become more important than ever. Lianjie Supply Chain, operating as a global sourcing platform in English, supports international buyers who require precise specifications, standardized measurements, and dependable equipment compatibility. Understanding rack units ensures smoother procurement, accurate planning, and long-term operational efficiency.

This article provides an in-depth, professional, and extended explanation of rack units, covering their definition, measurement standards, applications, planning strategies, advantages, challenges, and future relevance in global IT supply chains.

What Are Rack Units?

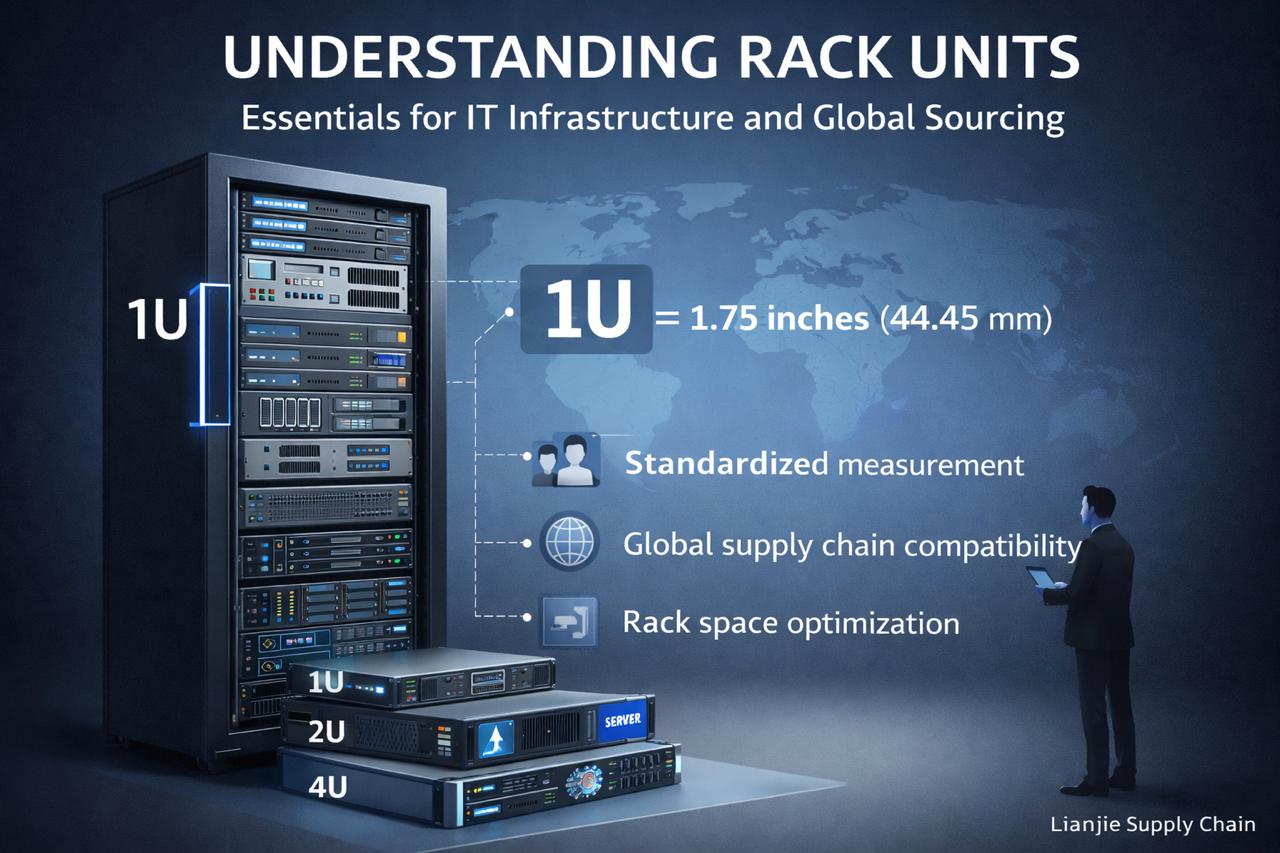

Rack units, commonly abbreviated as RU or simply U, are a standardized unit of measurement used to describe the vertical height of equipment designed to fit into a 19-inch server rack. This standard allows equipment from different manufacturers to fit seamlessly into the same rack framework.

One rack unit (1U) is equal to:

- 75 inches

- 45 millimeters

This measurement is universally accepted across the IT, networking, telecommunications, and industrial automation industries. Equipment height is typically described in whole numbers such as 1U, 2U, 4U, or larger, indicating how many rack units it occupies vertically.

By using rack units as a common measurement system, manufacturers, suppliers, and buyers can maintain consistency, ensure compatibility, and optimize space usage across different installations worldwide.

Historical Development of Rack Unit Standards

The rack unit standard emerged as a response to the growing complexity of electronic and computing equipment during the expansion of telecommunications and data processing systems. Before standardization, equipment dimensions varied significantly, leading to inefficiencies, compatibility issues, and increased installation costs.

The introduction of standardized rack units allowed:

- Manufacturers to design equipment with predictable dimensions

- Installers to plan rack layouts accurately

- Buyers to source equipment globally with confidence

Over time, rack units became an integral part of international equipment standards, supporting the rapid growth of data centers, enterprise IT systems, and global supply chains.

How Rack Units Are Measured and Structured

Rack units are measured vertically along the mounting rails of a standard 19-inch rack. These rails feature evenly spaced mounting holes that align precisely with rack unit increments.

Key Measurement Details

- 1U = 1.75 inches

- 2U = 3.5 inches

- 4U = 7 inches

- 42U rack height = 73.5 inches (approximately 1.87 meters)

Each rack unit includes a defined spacing pattern that ensures equipment aligns correctly with mounting hardware. This precision eliminates guesswork during installation and allows consistent equipment stacking.

Common Equipment Designed Around Rack Units

Rack units are used to house a wide range of equipment across industries. The most common examples include:

Servers

Rack-mounted servers are typically available in 1U, 2U, and 4U configurations. The choice depends on performance needs, cooling requirements, and expansion capacity.

Network Equipment

Switches, routers, firewalls, and load balancers are commonly designed to fit within standard rack units for easy integration.

Storage Systems

Network-attached storage (NAS) and storage area network (SAN) devices rely on rack units to scale capacity efficiently.

Power Distribution Units

PDUs are often mounted vertically or horizontally within racks to distribute power safely and efficiently.

Patch Panels and Cable Management

Patch panels, blanking panels, and cable organizers are measured in rack units to maintain order and airflow.

Why Rack Units Matter in IT and Data Centers

Rack units are far more than a simple measurement. They directly influence infrastructure efficiency, cost control, and system reliability.

Space Optimization

By using rack units, organizations can maximize vertical space and reduce the physical footprint of their IT environments.

Improved Airflow and Cooling

Proper allocation of rack units allows for strategic airflow design, reducing hotspots and improving thermal performance.

Predictable Scalability

Rack units make it easier to plan future expansions without redesigning entire systems.

Standardized Procurement

For global sourcing platforms like Lianjie Supply Chain, rack units simplify communication between suppliers and international buyers by eliminating ambiguity.

Rack Units and Global Supply Chain Efficiency

In international sourcing, precision is essential. Rack units provide a universal language that bridges geographic and manufacturing differences.

For China-based suppliers serving global markets, rack units help ensure:

- Accurate product specifications

- Reduced customization errors

- Faster order fulfillment

- Lower return and modification costs

Buyers can confidently source equipment knowing it will integrate seamlessly into existing rack systems.

Planning Rack Space Using Rack Units

Effective rack planning begins with a clear understanding of rack units and equipment requirements.

Step 1: Assess Equipment Needs

Identify the rack unit height required for each piece of equipment, including future upgrades.

Step 2: Consider Weight Distribution

Heavier equipment should be placed lower in the rack to maintain stability.

Step 3: Allow Space for Cooling

Leaving unused rack units between heat-generating devices improves airflow.

Step 4: Plan for Expansion

Reserve additional rack units to accommodate growth without disruption.

Common Rack Sizes and Configurations

Rack units are used within standardized rack heights, most commonly:

- 24U racksfor small installations

- 42U racksfor enterprise environments

- 45U and 48U racksfor high-density data centers

Each configuration serves different operational needs, balancing space availability, equipment density, and cooling capacity.

Challenges Associated with Rack Units

While rack units provide many benefits, improper planning can lead to challenges.

Overcrowding

Installing too many devices in limited rack units can restrict airflow and increase failure risks.

Inconsistent Equipment Depth

Although rack units standardize height, depth can vary, requiring careful compatibility checks.

Cable Congestion

Poor cable management can negate the benefits of standardized rack units.

Rack Units and Future Technology Trends

As technology evolves, rack units continue to adapt to new demands.

High-Density Computing

Modern servers deliver greater performance per rack unit, enabling more processing power in less space.

Modular Infrastructure

Rack units support modular designs that allow rapid deployment and replacement.

Sustainable Data Centers

Optimized rack unit usage contributes to energy efficiency and reduced environmental impact.

Role of Rack Units in Industrial and Non-IT Applications

Beyond traditional IT environments, rack units are used in:

- Industrial control systems

- Broadcasting and media production

- Telecommunications hubs

- Research laboratories

Their standardized nature ensures consistency across diverse applications.

Why Rack Units Are Essential for Professional Buyers

For professional buyers and sourcing specialists, rack units enable:

- Accurate quotations

- Reliable product comparisons

- Efficient logistics planning

- Reduced installation risks

Lianjie Supply Chain benefits from rack unit standardization by delivering clarity, reliability, and consistency to international clients.

Best Practices for Managing Rack Units

- Always document rack unit usage

- Use blank panels to control airflow

- Label equipment clearly

- Review rack layouts periodically

- Coordinate sourcing with standardized specifications

Conclusion

Rack units are a foundational element of modern IT and industrial infrastructure. They provide a standardized, reliable framework for organizing equipment, optimizing space, and ensuring compatibility across global supply chains. For international sourcing platforms like Lianjie Supply Chain, rack units are essential for bridging manufacturers and buyers with precision and professionalism.

By fully understanding rack units, businesses can reduce costs, improve efficiency, and build scalable, future-ready infrastructure. As global technology continues to evolve, rack units will remain a critical standard supporting innovation, sustainability, and operational excellence.